Custom Motorcycle Seats

We provide custom build motorcycle seats for B2B partners, including motorcycle brands, manufacturers, and parts dealer. With OEM/ODM options and flexible customization of materials, designs, color, and finishes, we ensure the perfect seats for your exact needs.

Get in touch today for a free custom solution.

Customization Services & Options

Structure & Ergonomics

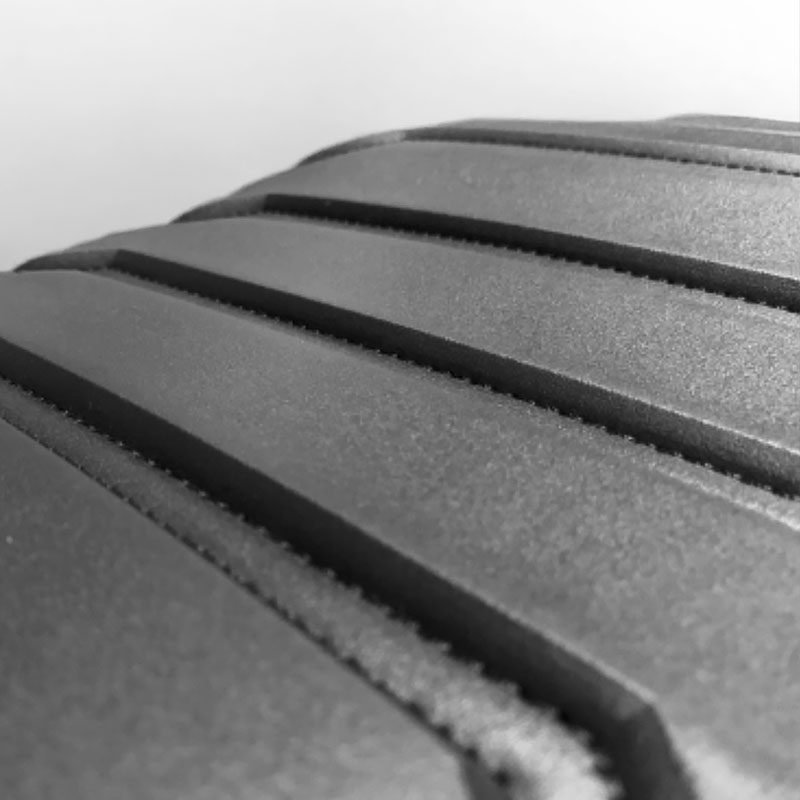

We use advanced injection molding and stamping technologies to produce a sturdy and durable baseplate for the seat’s foundation.

Single Bowl Sink

Single Bowl Sink

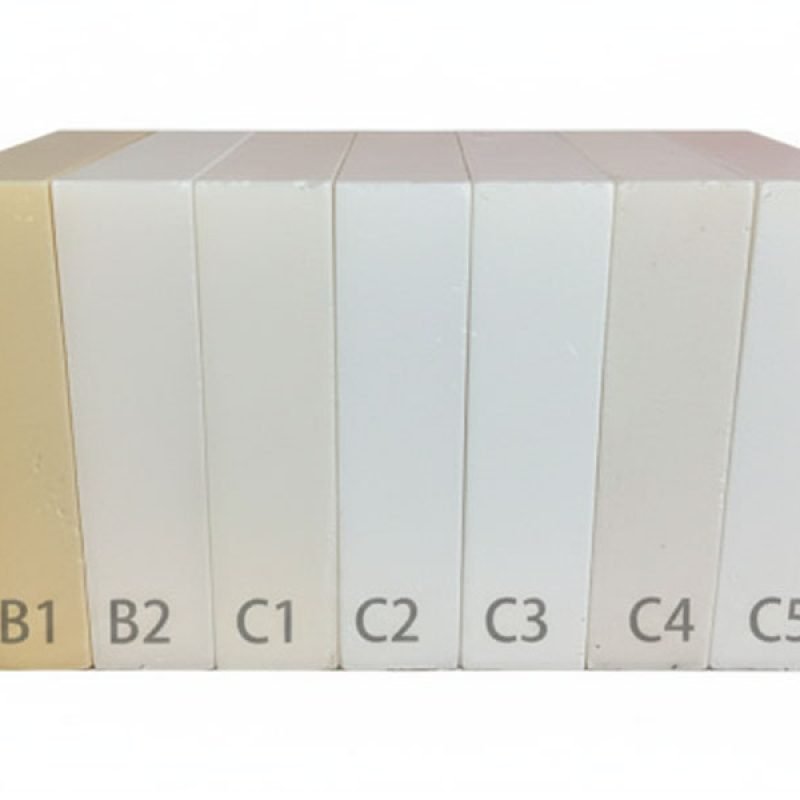

Foam Density & Firmness

Gel Inserts & Memory Foam

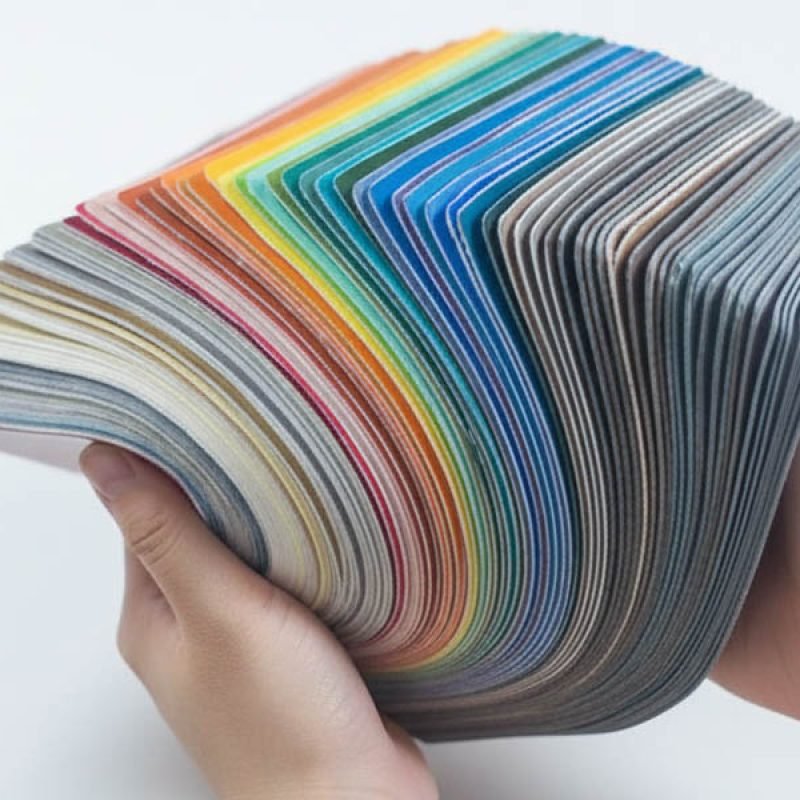

Aesthetics & Finishing

We use advanced injection molding and stamping technologies to produce a sturdy and durable baseplate for the seat’s foundation.

Single Bowl Sink

Single Bowl Sink

Single Bowl Sink

Single Bowl Sink

Waterproof Treatment

Single Bowl Sink

Single Bowl Sink

Single Bowl Sink

Motorcycle Seat Customization Process

Needs Analysis and Initial Design

Based on the data, drawings, or samples you provide, our design team can offer a complete and comprehensive motorcycle seat solution.

- Motorcycle seat sample

- Motorcycle seat design drawings or dimension data

- Motorcycle frame design drawings or dimension data

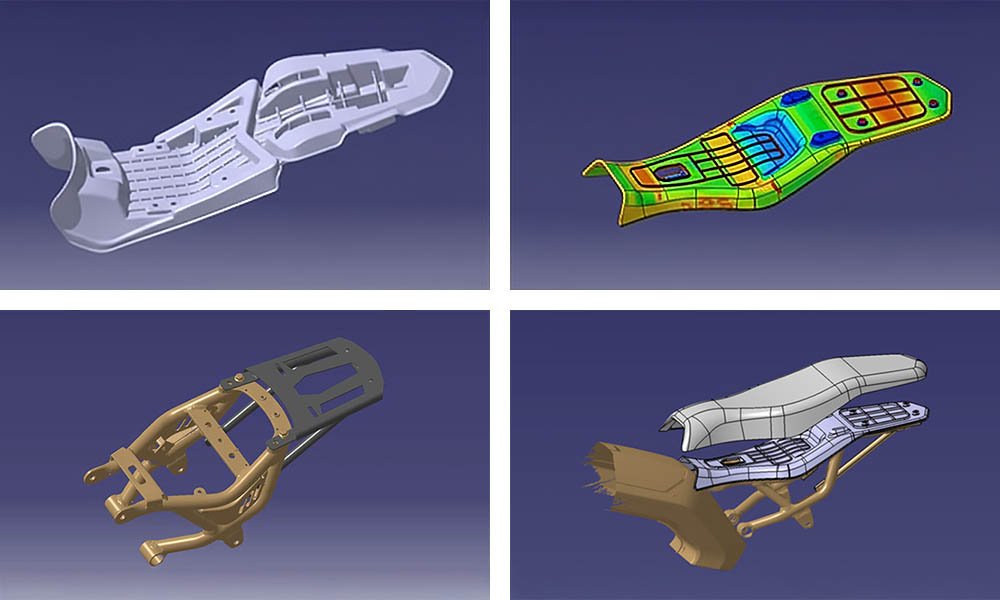

3D Modeling and Rapid Prototyping

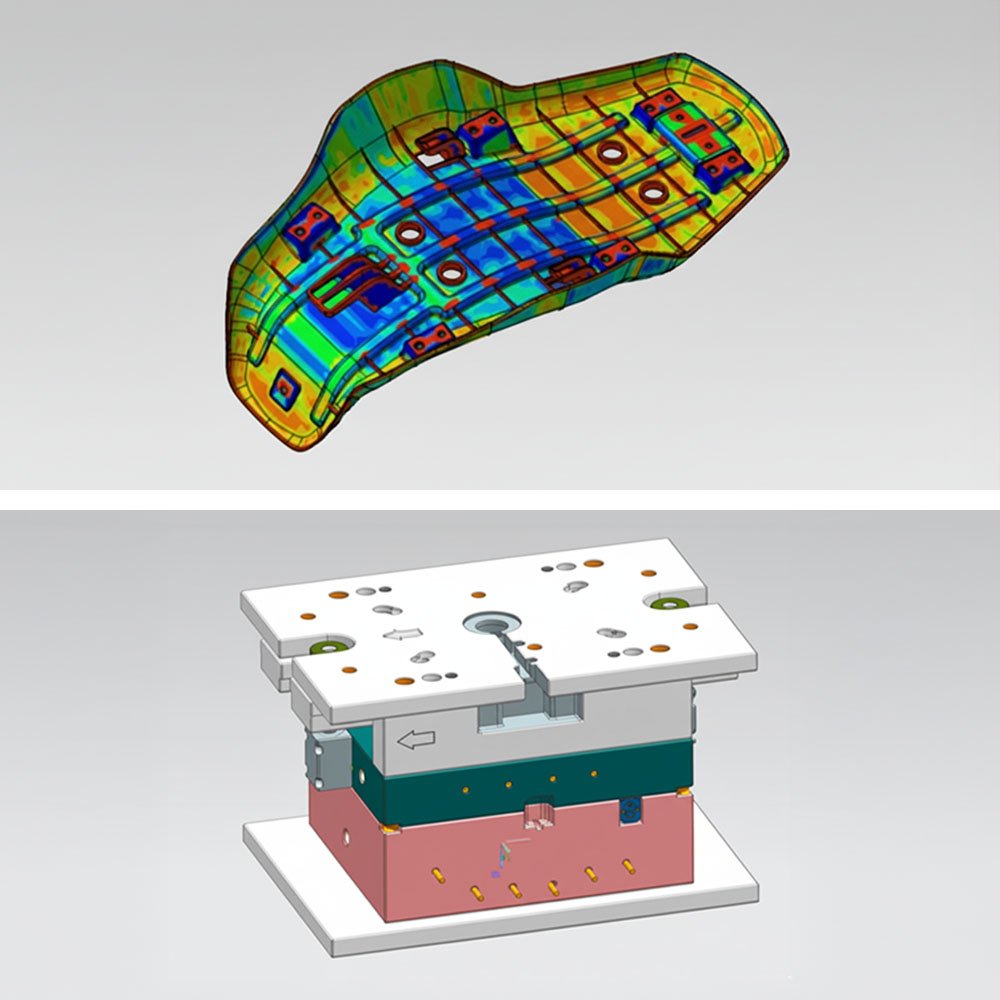

Based on your design, we will convert your input data into complete 3D engineering data. We then use advanced modeling and molding techniques to quickly verify the product’s overall design, ergonomic comfort, and structural integrity.

- Build 3D models for the baseplate and foam.

- Determine the manufacturing processes for the baseplate, foam, and seat cover, and select appropriate accessories.

- Produce a complete motorcycle seat prototype using 3D printing for the baseplate, CNC machining for the foam, and handcrafting the seat cover.

Product Suitability Analysis and DFM Evaluation

To ensure a smooth transition to mass production, we conduct a comprehensive technical analysis before mold development.

- We conduct in-depth analysis of the laws, regulations, and product suitability standards of the target sales country, ensuring the product is compliant and meets market standards.

- We perform a comprehensive DFM (Design for Manufacturability) evaluation on the mold to reduce the risk of mold development from the source, laying a solid foundation for subsequent large-scale production.

Mold Selection and Manufacturing

Based on your design requirements and budget, we will select the most suitable mold technology and materials to ensure the product achieves optimal quality.

- Motorcycle seat baseplates are typically produced using PP plastic injection molds. We also offer other manufacturing options, such as plastic blister molds, metal stamping molds, and fiberglass compression molds.

- For foam molds, you can choose between manually polished aluminum molds and CNC machined aluminum/steel molds.

- Other special accessories may also require rubber pad injection molds, stamping, and bending molds.

Pre-Production Sample Confirmation

After the molds are completed, we will produce 2-3 qualified motorcycle seat samples. Once both parties confirm and approve these samples, they will serve as the final benchmark for subsequent mass production and quality inspection.