Quality Management

Quality Management System

Our quality management system is built to support long-term OEM and custom motorcycle seat programs. It covers the entire lifecycle of a product—from raw material sourcing and in-process control to final inspection and pre-production validation.

By combining standardized procedures, documented controls, and experienced quality personnel, we ensure that every seat meets defined specifications for structure, comfort, appearance, and durability.

Incoming Material Quality Control

Behind every high-quality seat is a commitment to the raw materials.

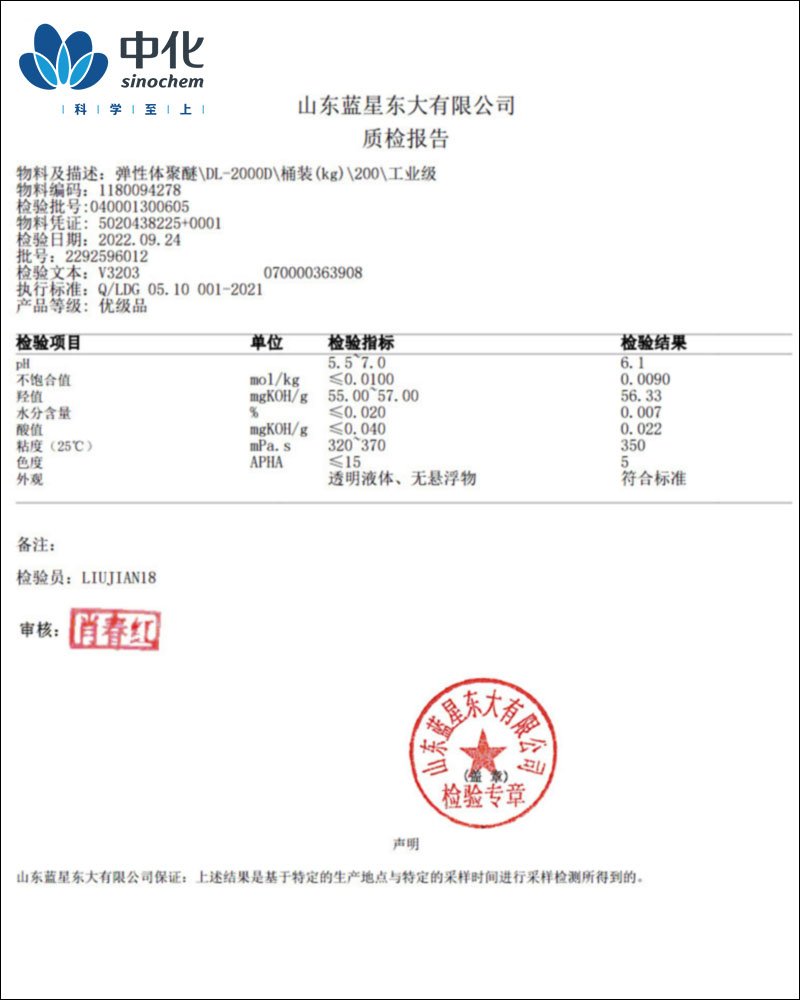

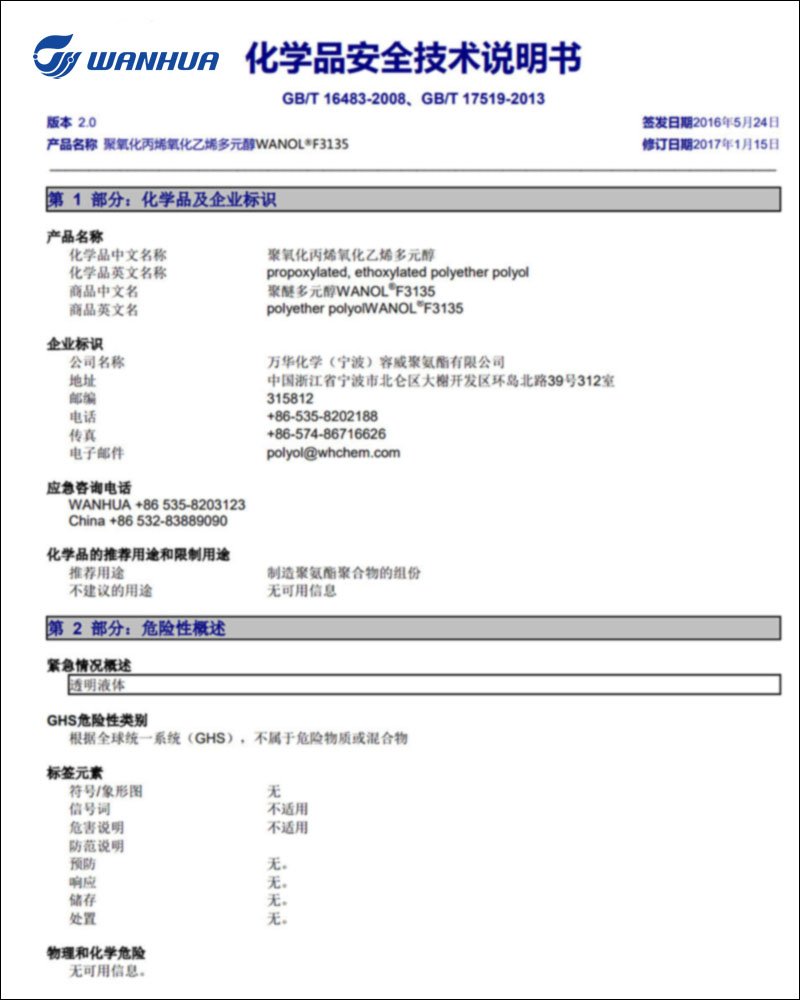

We monitor the quality of our raw materials with strict standards before entering production, ensuring their quality and stability meet our requirements through scientific testing and data tracking, we control potential risks at the source:

- Strict supplier evaluation

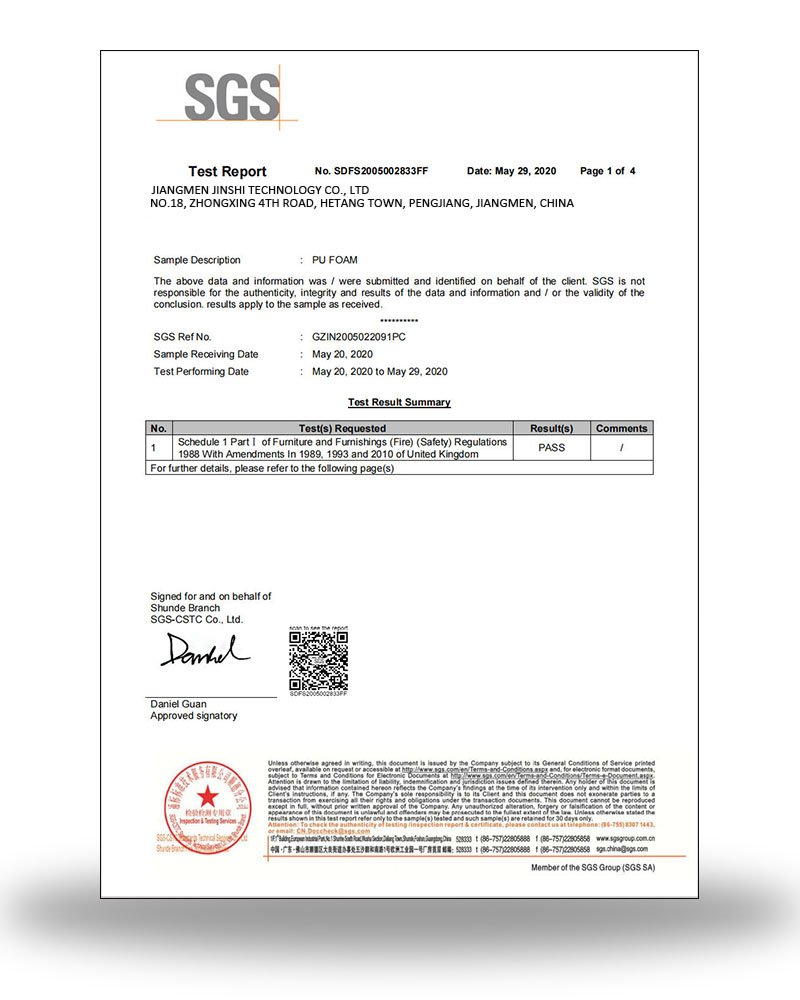

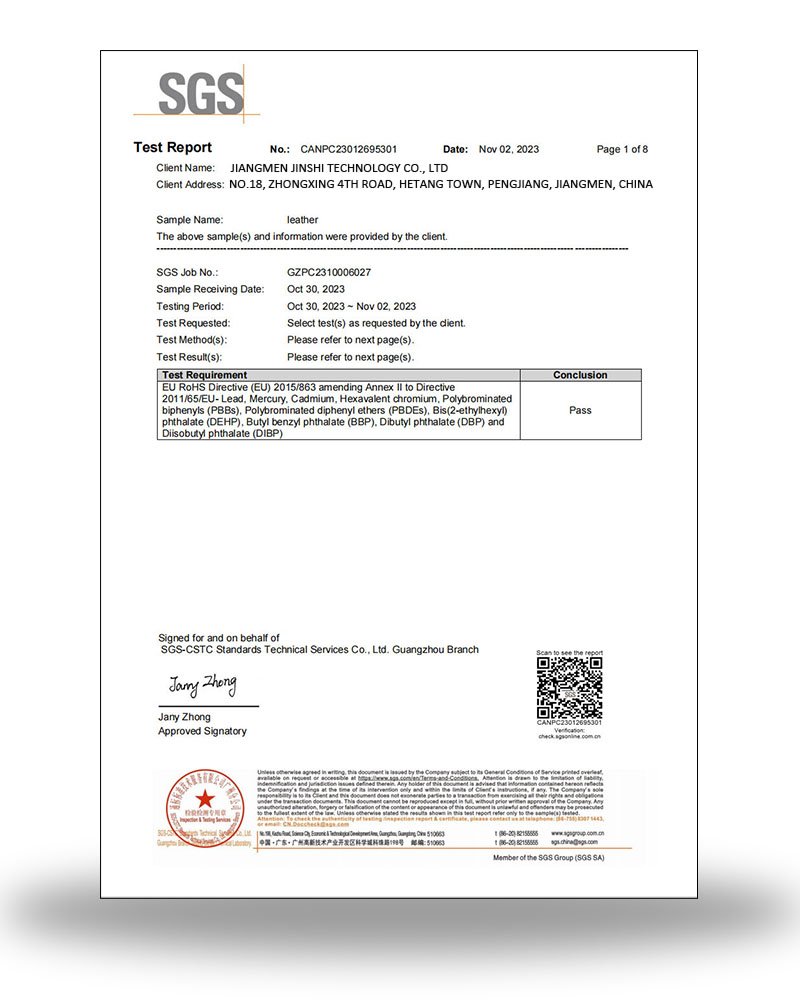

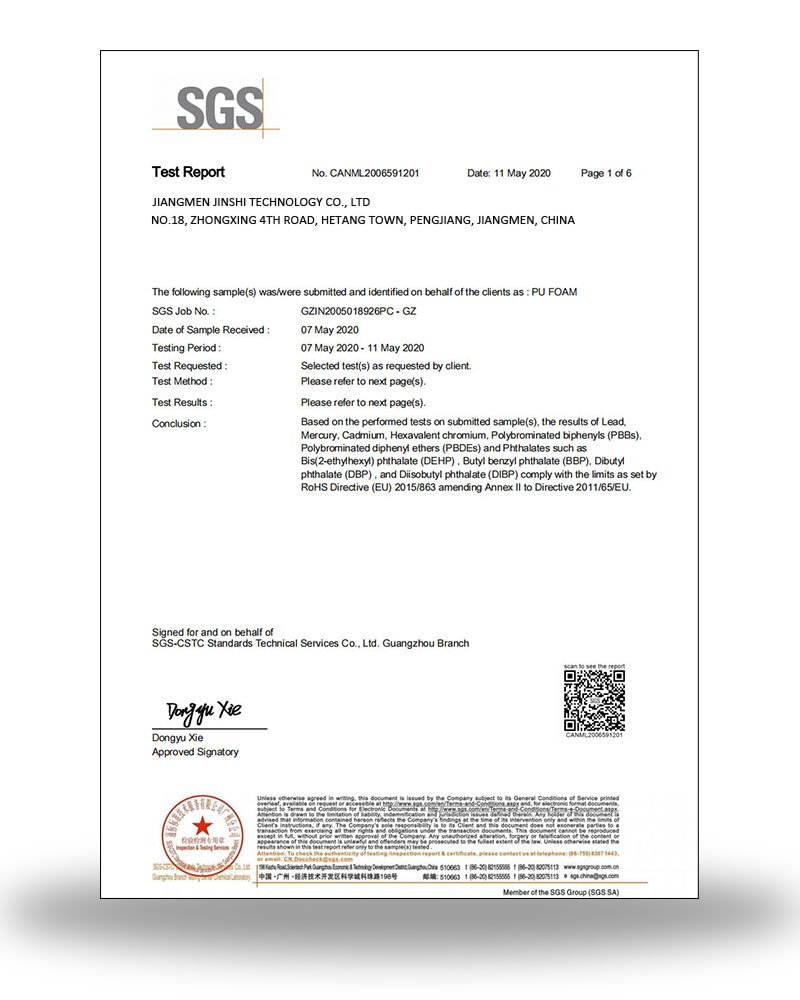

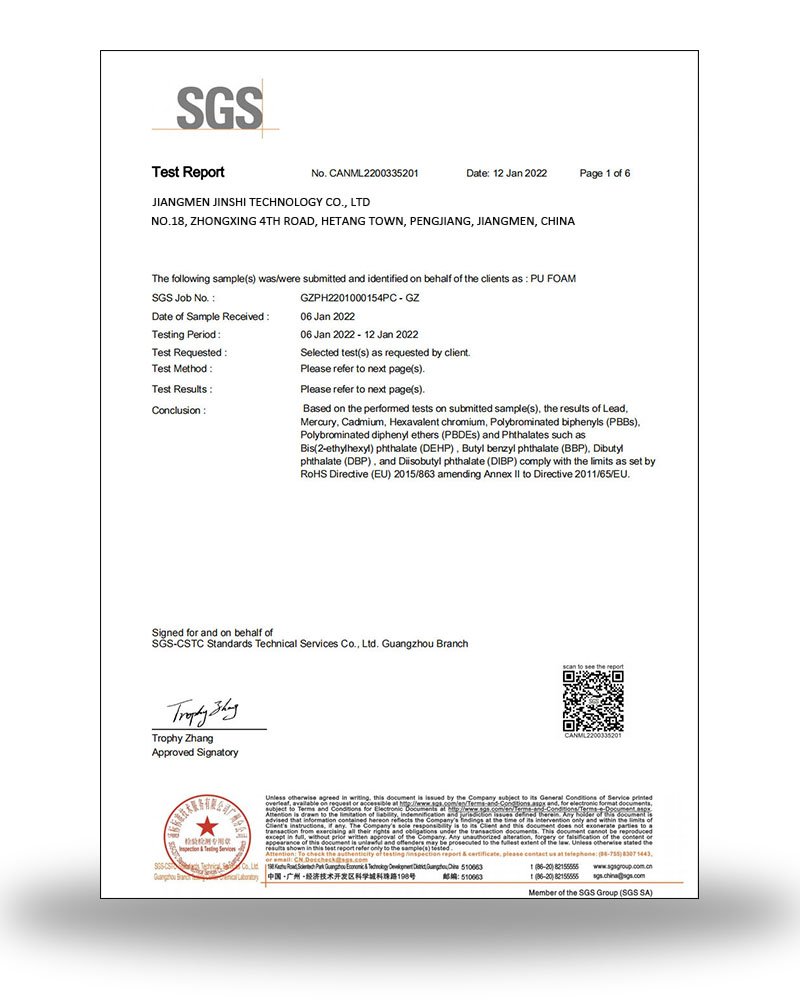

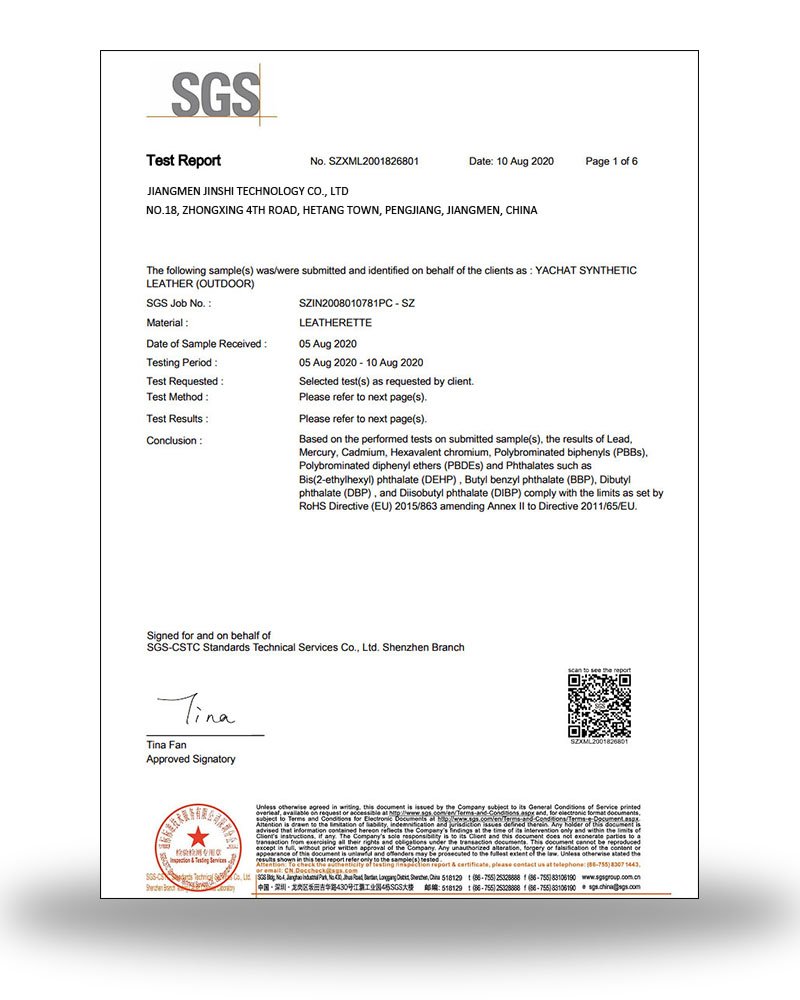

- Third-party testing assurance

- Complete data recording and traceability

- Smart monitoring and early warning systems

- Scientific storage conditions

- Periodic inspections

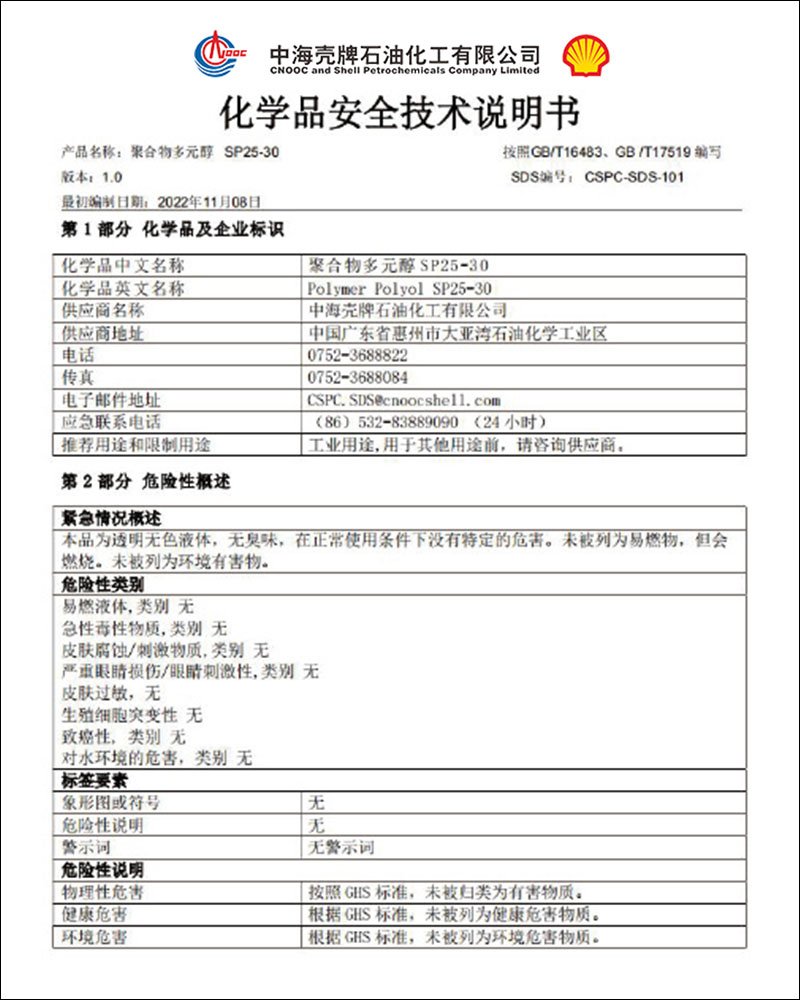

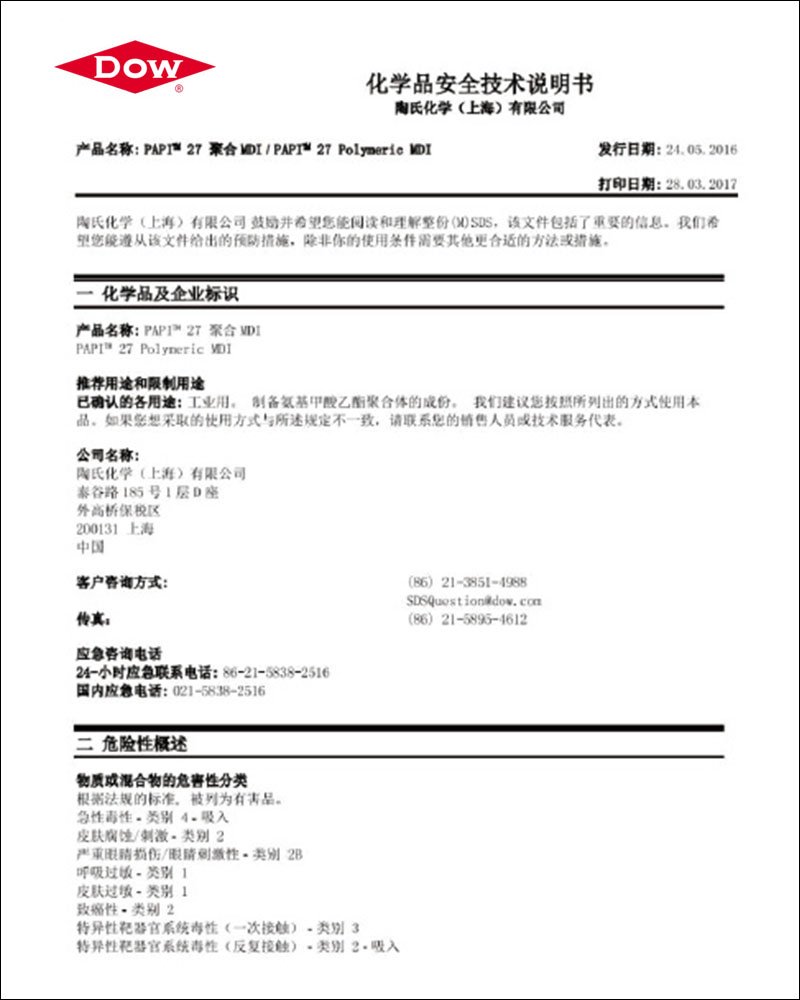

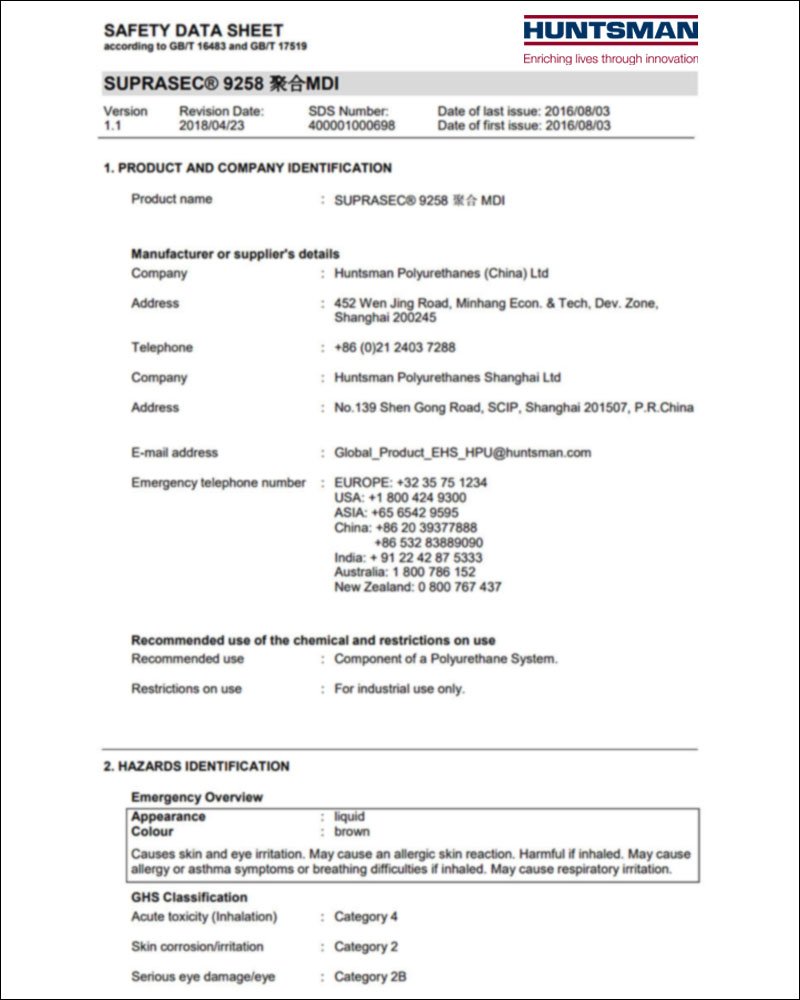

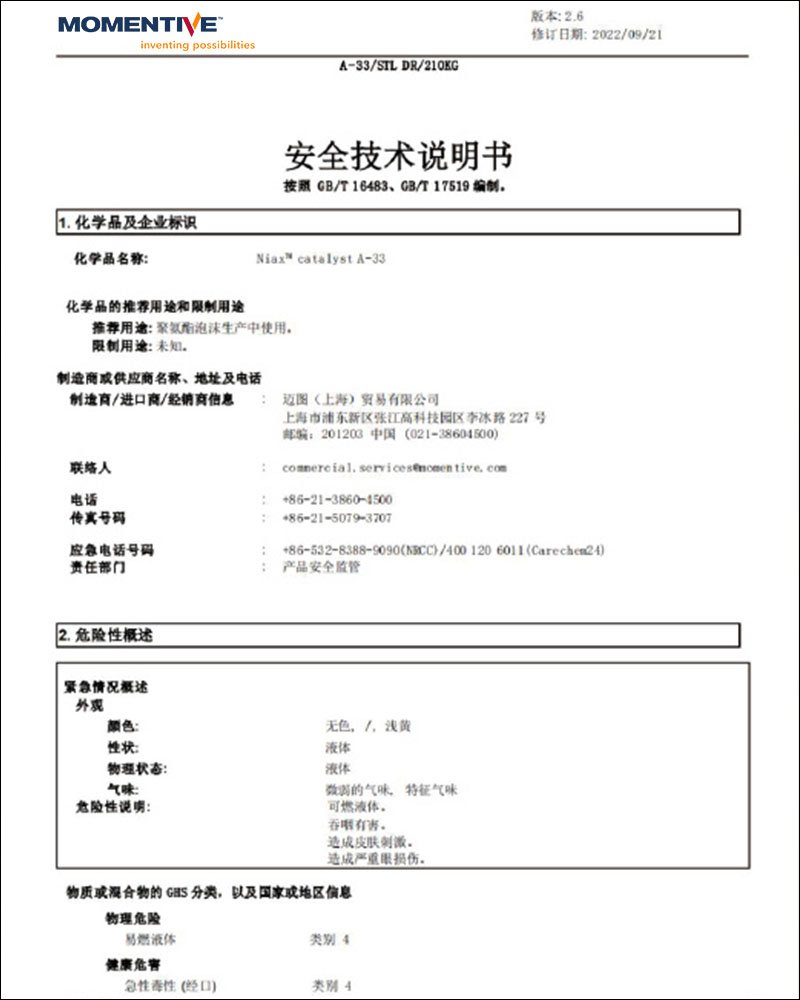

Foaming Material

Plastic Material

Leather Material

In-Process Quality Control

Quality control is continuously applied throughout the manufacturing process. Key production stages—including seat pan forming, foam molding, cover sewing, and final assembly—are monitored to ensure process stability and dimensional accuracy.

Standardized inspection points, first-article verification, and in-process checks help identify deviations early and prevent quality issues from progressing to later stages. Inspection records are maintained to support process consistency and continuous improvement.

Finished Product Inspection

Before shipment, all finished motorcycle seats undergo final inspection to verify appearance, dimensions, assembly integrity, and functional performance.

Inspection criteria are defined according to approved samples and project specifications. Only products that meet all acceptance standards are released for packing and delivery, ensuring consistent quality across every shipment.

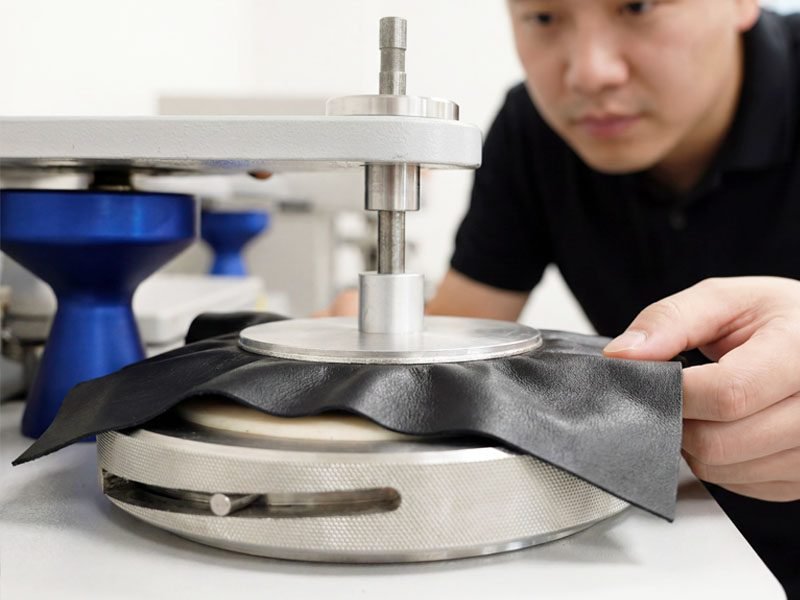

Reliability & Performance Testing

For new developments and pre-production validation, reliability and performance testing is conducted based on project requirements. These tests help verify material behavior, structural integrity, and durability under simulated usage conditions before mass production.

Motorcycle Seat Assembly

Motorcycle Seat Storage

Motorcycle Seat Stapling

Loading & Shipping

Guarantee of Quality and Responsibility

We supply motorcycle seat materials and products that can comply with international environmental and safety requirements, including RoHS and REACH (SVHC), based on project and market needs. Foam, seat pan, and upholstery materials can be selected or produced to meet additional performance requirements such as flame retardancy, mite resistance, and UV resistance.

All compliance claims are supported by third-party test reports and certifications, providing reliable assurance for OEM and custom programs.